Бүтээгдэхүүний тодорхойлолт

Laser welding machine is a kind of high-energy beam welding, generally using laser welding equipment for welding, laser welding is the use of high power coherent monochromatic photon stream focused laser beam as a heat source for welding.

The advantage is that it does not need to be carried out in a vacuum, and can carry out accurate energy control, so the welding of precision devices can be realized.

The competitive

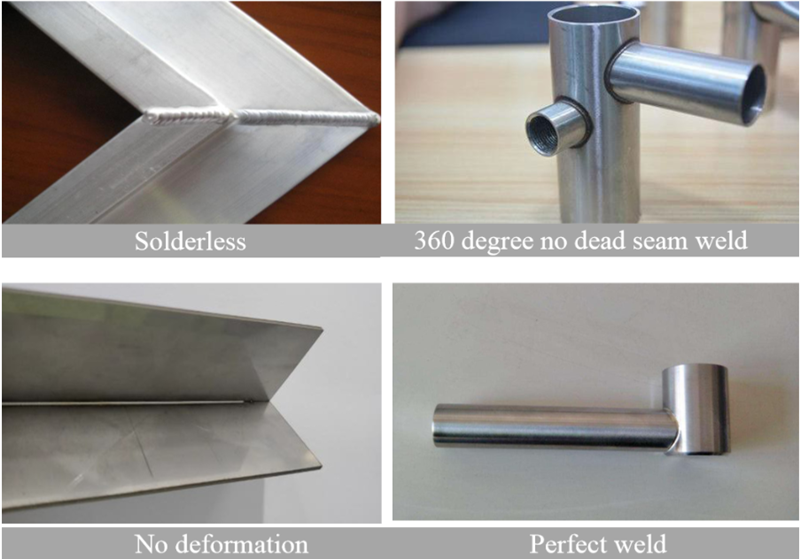

1. Selective energy applications in small areas: thermal stress reduction and thermal impact zone reduction with extremely low distortion

2. Narrow joint and smooth surface: reduce or even eliminate reprocessing

3. Combination of high strength and low welding volume: The welded workpiece can withstand bending or hydraulic forming

4. Easy integration: It can be combined with other production operations, such as alignment or bending

5. Only one side of the seam needs to be close

6. High process speed reduces processing time

7. Especially applicable to automation technology

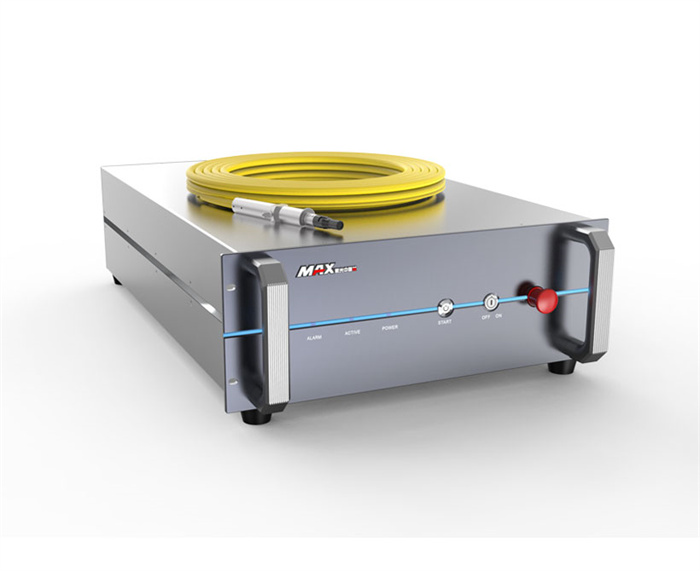

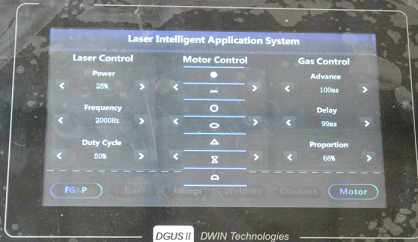

| Max laser output power | 1000W,1500W,2000W |

| Ажлын талбай | Continuous or modulate |

| Beam quality | M2<1.2 |

| Line width | <6nm |

| Straight modulate | 0-5KHZ |

| Хөргөлтийн систем | Ус хөргөх |

welding head water chiller

laser generator control system

Өргөдөл

Applicable Industry:

1. Widely applied in the fields of aeronautical and space, mechanism, electron, communication, dynamic,Chemical, automobile manufacture and other industries.

2. The welding of automobile spare parts, such as hydraulic pressure jib, gasoline cleaner, left gas sensor,Electromagnetic valve, and drive starting stator.

3. The close welding of lithium ion batteries, such as mobile phone batteries and power batteries.

4. In metallurgy industry, such as silicon steel plate welding.

5. The welding of engine and engine lamina in application military industry.

6. The precise spot welding of the electronic components and close welding of relay.

7. In electrical equipments industry, such as silicon steel sheet welding, the rotor of the air-conditioner Drive welding, and creepage protection welding.

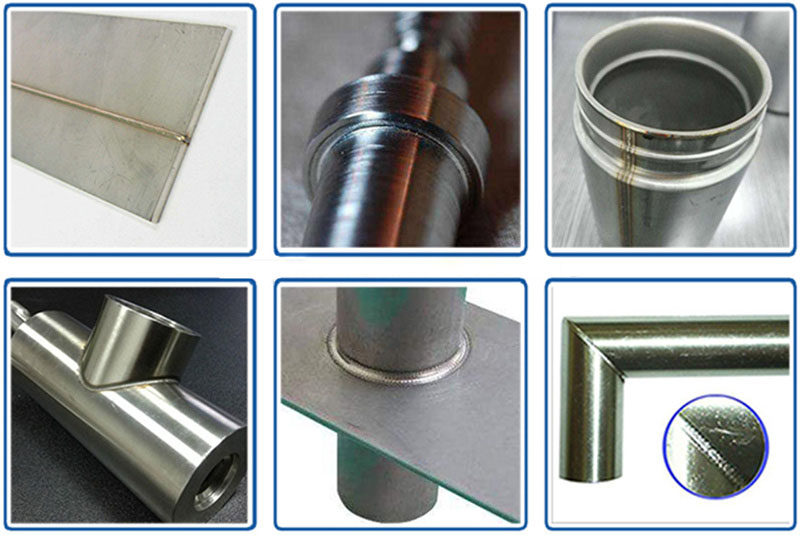

Applicable Materials:

Materials that can be welded are extensive: cold work alloy steel, hot work alloy steel, nickel tool steel, steel alloy, high

tenacity aluminum alloy, etc. Other metals like gold, silver, brass, aluminum-magnesium alloy, titanium, and platinum are also applicable.

Samples